Most of our systems are available in both rubber and polyurethane. TWG’s polyurethane products are produced using a higher-quality open-cast production method which results in better wear life and abrasion resistance than that found in injection-molded products. We source natural rubber instead of synthetic rubber, resulting in a longer-lasting rubber product.

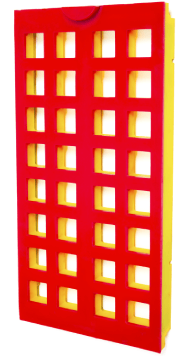

PROFRAME

There are a variety of media types that we can manufacture in a polyurethane frame to fit into a modular system where producers are looking for higher throughput.

FEATURES & BENEFITS

- Can fit into modular systems of all sorts.

- Screen media is molded into a polyurethane frame for ease of installation.

- Squares, slots, Zs, perforated plate, and welded wire can be framed with polyurethane.

- Wire inserts offer more open area versus many polyurethane systems.

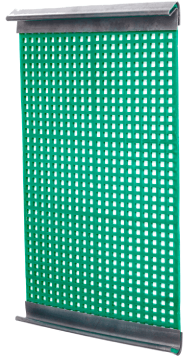

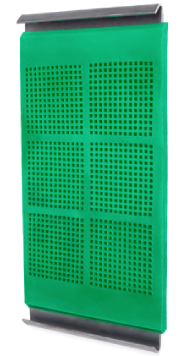

WESTCOAT

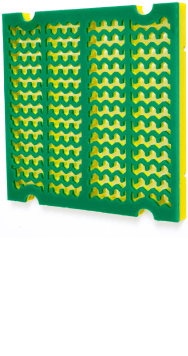

Westcoat combines the life of polyurethane with the open area of wire cloth, and can be used as a direct substitute for tensioned wire cloth screens, offering up to 5 times the life of wire cloth.

FEATURES & BENEFITS

- Improved wear life over wire.

- Direct replacement of wire cloth on crown decks without altering machine structure.

- Higher open area than other synthetics.

- Finished screen edges for easy screen handling.

- Can be manufactured without openings for high-wear areas.

Westcoat

Wescoat band cross-section

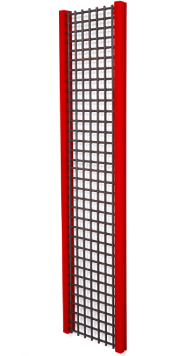

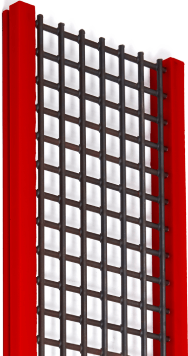

WESTRAIL / POWERRAIL

Westrail is TWG’s 12″x24″ modular polyurethane panel system. Powerrail is the same size panel but in rubber. TWG’s locking system allows panels to be mixed across the deck. Customers have the option of dual-colored modules to assist in determining proper changeout time.

FEATURES & BENEFITS

- Dual-colored panels indicate when panels need to be replaced.

- Improved wear life versus wire screening.

- Poly-to-poly (and rubber-to-rubber) press fits increase wear life.

- 24″ length results in fewer sub-structure requirements.

- Flat decks allow for effective screening across the entire deck.

- Multiple opening styles: squares, slots, rounds, Zs.

- Excellent for aggressive and long-running situations.

Westrail

Dual-color Westrail

Powerrail

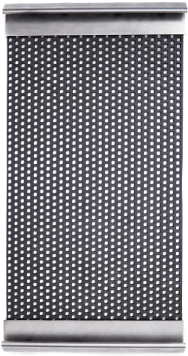

WESTVIBE / POWERVIBE

Westvibes and Powervibes are light-duty flexible polyurethane or rubber standard tensioned screens with small openings and are approximately 1/2″ thick. Crown bar locations are blocked out, which enhances wear life.

FEATURES & BENEFITS

- Openings up to 1/2″.

- Flexibility reduces plugging and blinding.

- Reinforced with high-tensile cable.

- Recued noise generation over metal decks.

- No deck modification required.

Westvibe

Powervibe

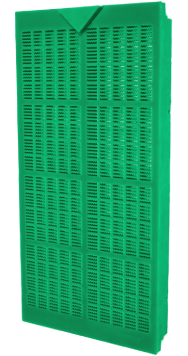

WESTFLEX / POWERFLEX

Westflex and Powerflex provide a heavier-duty version of our Westvibes and Powervibes.

FEATURES & BENEFITS

- Available up to 4″ openings.

- Flexibility reduces plugging and blinding.

- Reinforced with high-tensile cable.

- Recued noise generation over metal decks.

- No deck modification required.

Westflex

Powerflex

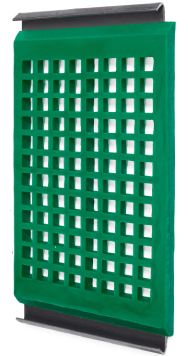

WESTDECK / POWERDECK

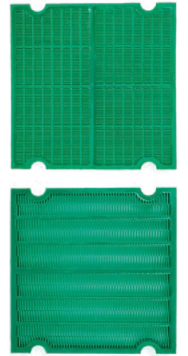

Westdeck is TWG’s 12″x12″ modular polyurethane panel system. Powerdeck is the same locking style but in rubber, and also comes in 12″x24″ size. TWG’s locking system allows

panels to be mixed across the deck. We manufacture these 12″x12″ panels in variable thicknesses.

FEATURES & BENEFITS

- Improved wear life versus wire screening.

- Dual-colored panels indicate when panels need to be replaced.

- Flat decks allow for effective screening across the entire deck.

- Multiple opening styles; squares, slots, rounds, Zs.

- Resident pins allow for quick changeouts without new pins.

Westdeck

Dual-color Westdeck

Powerdeck

STANDARD ACCESSORIES

Polyurethane Crown Bar Protectors

Z-Cleats, Wedges & Sideliners

Male & Female Locking Pins

Clamp Rails

Rubber Covered Clamp Rails

Screen Bolts, Nuts and Washers

J-Bolts and Protectors

HIGH-QUALITY

AND LOCAL STOCK

WE COVER ALL YOUR

SCREEN & ACCESSORY NEEDS

GOT QUESTIONS?

WE'VE GOT ANSWERS

FIND US ON: